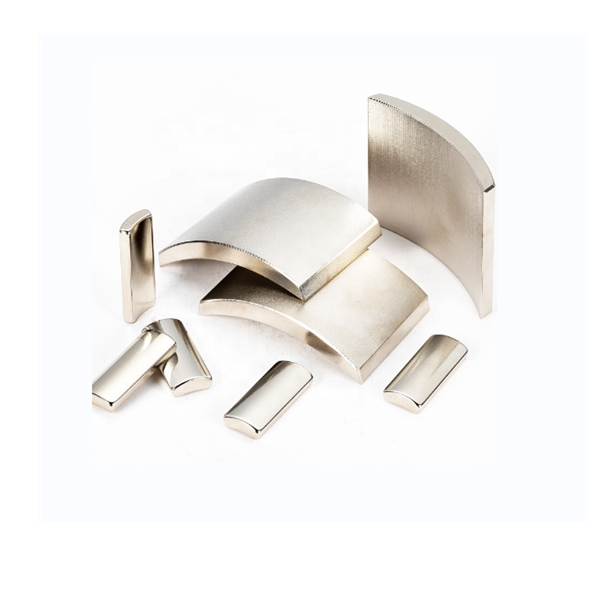

Best quality Small Thin Strong Magnets - N52 Super Strong Neodymium Arc Segment Magnets for Flywheel – Hesheng

Best quality Small Thin Strong Magnets - N52 Super Strong Neodymium Arc Segment Magnets for Flywheel – Hesheng Detail:

HESHENG MAGNET GROUP

Professional Effective Fast

Product Details

About Arc Magnet

As the third generation of rare earth permanent magnet, Neodymium magnets are the most powerful commercially produced magnets. Neodymium arc magnet, also known as Neodymium curved magnet, is a unique shape of Neodymium magnet, then almost all of Neodymium arc magnet is used for both rotor and stator in permanent magnet (PM) motors, generators, or magnetic couplings.

The size,shape and grade of magnet can be produce according to your request.

Dimensions: Accourding to the design drawing

Tolerance: +/-0.05mm ~ +/-0.1mm

Material: NdFeB,N35~N52 Grade

Plating/Coating: Zc,Ni(Ni-Cu-Ni),Epoxy(Ni-Cu-Epoxy)

Max Operating Temp: 80~220 degree centigrade

Magnetization Direction: Diametrical magnetized

【Can I customize products? 】

Yes, Custom Magnets Are Available.

Please tell us the size, grade, surface coation and quantity of the magnet, you will get the most reasonable quotation quickly.

>Magnetization Direction and Coating include

>Our Magnets are Widely Application

How to Enhance Motor Performance by Optimization of Arc Magnet

The vast majority of Neodymium arc magnet serve as motor magnet. Besides magnetic performance and surface treatment, both shape and structure of the magnet have significantly impacts on the motor performance. It is a challenge for slotted motor to avoid cogging torque caused by interaction between the magnet and the stator tooth. In order to suppress torque ripple, vibration, and noise generated by cogging torque, curved magnet in either frequently-used radial flux motor or axial flux motor can be modified into the skewed shape. Eddy current is generally leading the temperature rise in the permanent magnet and caused demagnetization. Hence decreased the working efficiency of the motor. Laminated arc magnet which made by bonding several pieced of thin magnet together can dramatically reduce the eddy current loss without replacing the original structure and performance of the motor.

We also can supply L-T Series magnets with low weight loss, for wind turbines generators, tide generators, marsh gas generators,elevators engine, which have to ensure high reliability on function, this will help them to increase the ability of Corrosion resistance, and prolong the use age, get down the maintain cost of facility.

Our Company

Hesheng Magnet Group

1. We have over 30 years experience in magnet industry, providing one-stop service of slicing, punching, special machining, CNC lathe,electroplating, magnetic circuit design and assembly.

2. More than 6,000 domestic and foreign customers’ choice. Top 500 companies’ designated magnet supplier

3. The senior engineers have deep research and proficient to raw material principles and applications for more than 20 years,providing technical support and optimal cost solution.

4. More than 20 years stable supply chain to ensure same quality between samples and large goods and every batches.

5. Neodymium Permanent Magnet is customized, the grade we could produce is N35-N52(M,H,SH,UH,EH,AH), for the grade and shape of the Magnet, if you need, we could send you the catalogue. If you need technical support about the Permanent Magnet and Neodymium Permanent Magnet Assemblies, we could give you the biggest support.

6. One to one and professional project team service, provide solutions within 12 hours.

Processing and Production Equipment

Step : Raw Material→Cutting→Coating→Magnetizing→Inspection→Packaging

Our factory has strong technical force and advanced and efficient processing and production equipment to ensure that the bulk goods are consistent with the samples and to provide customers with guaranteed products.

Quality Inspection Equipment

Excellent quality testing equipment to ensure product quality

Complete Certificates

Note: Space is limited, please contact us to confirm other certificates.

At the same time, our company can carry out certification for one or more certificates according to your requirements. Please contact us for details

Saleman Promise

Packing & Sale

Performance Table

Chat Now

Product detail pictures:

Related Product Guide:

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Best quality Small Thin Strong Magnets - N52 Super Strong Neodymium Arc Segment Magnets for Flywheel – Hesheng , The product will supply to all over the world, such as: Paris, Jersey, United Arab emirates, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.