Wholesale Super Strong Various Shapes Magnetic Welding Positioner

Professional Effective Fast

Wholesale Super Strong Various Shapes Magnetic Welding Positioner

Over the last 15 years Hesheng export 85% of its products to American, European, Asian and African countries. With such wide range of neodymium and permanent magnetic material options, our professional technicians are available to help solve your magnetic needs and choose the most cost effective material for you.

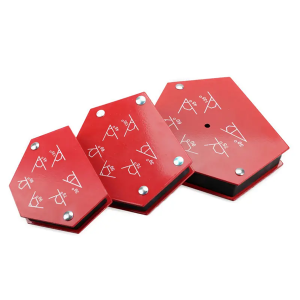

Style has Mini, Small, Medium, Large and Supper.

Support ODM / OEM , Samples Service

Welcome to inquiry!

Magnetic welding positioners are an essential tool in modern welding operations. They are designed to facilitate the welding process and make it simpler and more efficient. These positioners provide welders with the ability to hold the workpiece in the desired position, ensuring that the welding process is conducted accurately and seamlessly.

The key advantage of magnetic welding positioners is their ability to hold the workpiece in place without the need for clamps or other tools. This feature greatly simplifies the welding process and allows welders to work more efficiently. Additionally, magnetic welding positioners can be rotated 360 degrees, making it easier to weld pieces from different angles.

|

Product Name

|

Welding magnet, magnetic welding holder, magnetic welding positioner

|

|

Shape

|

Arrow, Mini, Polygon, Bevel Angle, etc...

|

|

Holding Force

|

11 lbs to 165 lbs (5kg to 75kg)

|

|

Spcifications

|

Various, check the follow pictures

|

|

MOQ

|

10 PCs

|

|

Delivery Time

|

1-10 days, according to inventory

|

|

Packing

|

Blister Box

|

|

Certificates

|

REACH, ROHS, EN71, CE, CHCC, CP65, IATF16949, ISO14001, etc...

|

|

Transportation

|

Door to door delivery. DDP, DDU, CIF, FOB, EXW are supported

|

|

Payment Term

|

L/C, Westerm Union, D/P, D/A, T/T, MoneyGram, Credit Card, PayPal, etc..

|

|

After Sales

|

Compensate for damage, loss, shortage, etc...

|

Product Description

Magnetic Welding Positioner

1. Shape

3. Shell

●Double sided rivet process

4. Built-in Magnet

5. Silver Model

Products Parameters

【Package 】

We can help you custom package.

Magnetic welding positioners are easy to use and maintain. They are also durable and can withstand the high temperatures and harsh environments common in welding operations. Additionally, these tools save time and money in the long run since welders can complete their work faster and with greater precision.

Our Company

Processing and Production Equipment

Step : Raw Material→Cutting→Coating→Magnetizing→Inspection→Packaging

Our factory has strong technical force and advanced and efficient processing and production equipment to ensure that the bulk goods are consistent with the samples and to provide customers with guaranteed products.

Quality Inspection Equipment

Excellent quality testing equipment to ensure product quality

Complete Certificates

Note: Space is limited, please contact us to confirm other certificates.

At the same time, our company can carry out certification for one or more certificates according to your requirements. Please contact us for details

Saleman Promise

Packing & Sale