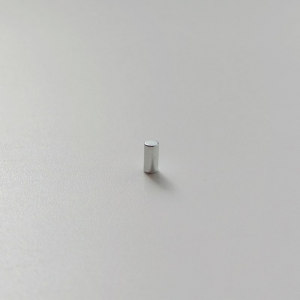

Top Magnet Neodymium Supplier Very Small Cylinder NdFeB Magnet

Professional Effective Fast

Top Magnet Neodymium Supplier Very Small Cylinder NdFeB Magnet

Over the last 15 years Hesheng export 85% of its products to American, European, Asian and African countries. With such wide range of neodymium and permanent magnetic material options, our professional technicians are available to help solve your magnetic needs and choose the most cost effective material for you.

Product Details

Product Display

Advanced production equipment and 20 years of production experience can effectively help you customize various shapes! Special shaped magnet (triangle, bread, trapezoid, etc.) also can be customized!

>Neodymium Magnet

【Can I customize products? 】

Yes, We customize magnets according to your requirements.

Please tell us the size, grade, surface coation and quantity of the magnet, you will get the most reasonable quotation quickly.

Size Tolerance ( +/-0.05mm ) +/-0.01mm is possible

a. Before grinding and cutting, we inspect the magnet tolerance.

b. Before and after coating, we will inspect the tolerance by AQL standard.

c. Before delivery, will inspect the tolerance by AQL standard.

PS: Product size can be customized. AQL(Acceptable quality standards)

>Magnetization Direction and Coating include

The Above Chart is a list and description of common plating options for custom magnets. Why do magnets need to be plated?

❃ Oxidization (Rust)

Nd-Fe-B magnets will oxidize(rust) if left exposed in air. When a plating wears down or cracks, the exposed area will oxidize. An oxidized area will not result in complete degradation of the magnet, only the oxidized area will lose its strength. However the magnet will lose some structural integrity and become more susceptible to breakage.

❃ Durability

Depending on shape, permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

❃ Harsh Environments

Plating vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are

commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating. The most comm!on type of plating for neodymium magnets Nickel (Ni-Cu-Ni) Intended for indoor use. It has proven to be very resilient when subjected to normal wear and tear. However it will corrode outdoors in prolonged exposure to salt water, salty air, or harsh chemicals.

>Our Magnets are Widely Application

Our Company

Hesheng magnet group Established in 2003, Hesheng Magnetics is one of the earliest enterprises engaged in the production of neodymium rare earth permanent magnets in China. We have a complete industrial chain from raw materials to finished products. Through continuous investment in R&D capabilities and advanced production equipment, we have become the leader in the application and intelligent manufacturing of neodymium permanent magnets field. after 20 years development,and we have formed our unique and advantageous products in terms of super sizes, magnetic Assemblies,special shapes, and magnetic tools.

Our company has passed relevant international system certifications such as ISO9001, ISO14001, ISO45001 and IATF16949.Advanced production inspection equipment, stable raw material supply, and complete guarantee system have achieved our first-class cost-effective products. We have been maintaining extensive and in-depth cooperation with many well-known domestic and overseas enterprises, such as BYD, Gree, Huawei, General Motors, Ford, etc.

Processing and Production Equipment

Step : Raw Material→Cutting→Coating→Magnetizing→Inspection→Packaging

Our factory has strong technical force and advanced and efficient processing and production equipment to ensure that the bulk goods are consistent with the samples and to provide customers with guaranteed products.

Quality Inspection Equipment

Excellent quality testing equipment to ensure product quality

Complete Certificates

Note: Space is limited, please contact us to confirm other certificates.

At the same time, our company can carry out certification for one or more certificates according to your requirements. Please contact us for details

Saleman Promise

Packing & Sale

Performance Table